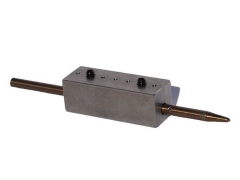

Speardiver Spear Shaft Drilling Jig

Guides a 3/32" drill bit to make a flopper pin hole

The Speardiver Shaft Drilling Jig guides a 3/32" drill bit, which is the standard diameter for a flopper pin, to make perfectly centered holes in shafts ranging from 5/16" (8mm) in diameter and down including: 7.5mm, 9/32" (7mm) and 6.5mm. The 3/32" hole can then be used as a pilot hole if a larger diameter hole is needed. The jig is 3" long X 1" wide X 1" tall.

- Quickly and easily change the length of a shaft and reposition the flopper

- Add a pin for loading another band

- Increase band stretch by putting a pin closer to the trigger mechanism

- Add a rest pin for ease of loading

- Add a pin to keep one band at minimal stretch when powering down, rather than leaving it to flop around

- Add a pin to rig a Heinrich line release

- Make stringers from old bent shafts

How to use the jig

Slide the shaft in the jig, choose one of the 5 holes and position it over where you want the hole to be. Tighten the two Allen set screws, the shaft is then held securely and the jig automatically centers and guides the drill bit. With a drill press hand pressure is enough to hold the jig and shaft in place under the bit. If a hand drill is used the jig can be secured in a vice. After drilling the hole turn the jig upside down, there are 9/32" holes on the bottom of the jig corresponding to the 3/32" holes on the top, use a 9/32" drill bit in a hand drill to de-burr the bottom of the new hole and allow removal of the shaft from the jig. Blow out all debris so as not to jam the jig, loosen the Allen screws and slide the shaft out of the jig.